Profile

To order a print

click here to go to the PRINTS page.

STREET LIGHTING

Since they were first introduced some 150 years ago electric street lights have become a lot brighter and much more widespread. We now have lights in country lanes and in tube stations deep underground.

Lighting is apparently responsible for 1/4 of the world’s electricity consumption. In Australia it is estimated that public lighting generates as much as 50% of local government greenhouse gas emissions.

Perhaps of more concern is the observation that cities in America emit 3–5 times more light than those in Germany. Over-illumination is estimated to waste the equivalent of two million barrels of oil every day.That is enough energy to make 21 cups of tea for every person on the planet.

HISTORY

The Greeks and Romans both had limited forms of street lighting with Roman 'lanternarius' slaves appointed to light and maintain the candle or oil lamps in front of their villas. The first public gas street lighting was demonstrated by Fredrick Winsor in Pall Mall in London on January 28, 1807. Oil Gas appeared as a rival to coal-gas in 1815 with John Taylor patenting an apparatus for its production. Kerosene street lamps were introduced in Lviv in the Austrian Empire in 1853 followed by electric street lighting employing an arc lamp system developed by the Russian Pavel Yablochkov in 1875. Joseph Swan first lit Mosley Street, in Newcastle upon Tyne with an electric incandescent system in 1879.

Today’s lighting commonly uses high pressure sodium HPS lamps which provide good levels of light for limited amounts of electricity. However new technologies, such as LED or induction lights can provide higher levels of illumination with lower wattages promising to replace existing street lights.

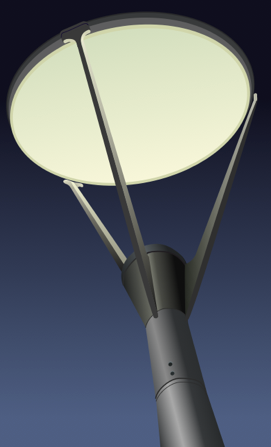

MAKING

The canopy of the Marshall ‘Geo Parklight’ is made from a cast aluminium alloy with the reflector painted to cast the light downwards. The aluminium is mixed with silicon to provide a lightweight corrosion resistant alloy which is widely used in engineering structures. A measured amount of heated metal is pushed into a steel mould by a hydraulic piston. Here it cools and solidifies enough to be ejected as the finished form.

The components are then anodised in an electrolytic process which changes the crystal structure near the surface to make it weather resistant.

DRAWING

The components of the lamp are simple well considered forms which makes them ideal for the composition. However the acute angle of view creates the need for careful drawing and precise detailing. The evening lighting with the bright reflector shining out makes some dramatic contrasts of light and dark. To make the reflector appear to glow is a particular drawing challenge.