Buy a print

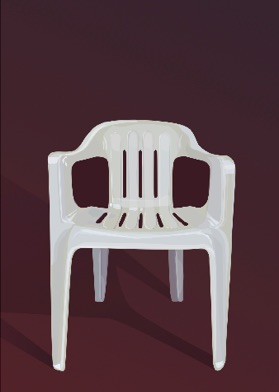

PLASTIC CHAIR

‘Silla Selva’ is a one piece plastic chair made by Balliu in northern Spain. It stems from a design innovation of the 1960‘s which created these strong, lightweight structures that are made in one moulding operation. These chairs are now widely used in gardens and outdoor spaces where they are weather resistant, stackable and easy to clean.

HISTORY

Ornate chairs can be found in the tombs of Egyptian Pharos and by the 16th Century a few less decorative versions would be seen in middle class homes in Europe. It, however, was not until the mid 1800’s that factory made chairs became everyday items for all to use.

A traditional wooden chair is expensive to make. A similar model to the one depicted is typically made from some 16 to 24 different parts. Each piece has to be cut and shaped before being joined and finished.

The first all plastic chair was designed by Joe Colombo in Milan between 1965 and 67. Called ‘Universale’ it had an integral seat and back and two sets of legs, one for an adult and another for children. The first one piece plastic chair, ‘Selene’ was moulded from polyester and fibreglass, and designed by Vico Magistretti in1967.

MAKING

As the ‘Monobloc’ this concept was refined by manufacturers such as Allibert in France and Grosfillex in the USA. From the 1970’s they invested in expensive large scale steel moulds to mass produce one piece polypropylene chairs.They are made by a process called Injection Moulding. A hot fluid plastic is forced into the cavity in a heated steel mould. Once full the mould is chilled by pumping cold water into channels throughout the mould. When cooled the mould is opened and the rigid chair removed.

DRAWING the PLASTIC CHAIR

The shapes curve and merge into the various forms which make up the chair. These changes create subtle variations of tone on surfaces with darker areas contrasted by the small intense areas of highlight.The curved edges and rounded corners catch and reflect the light in particular ways which have to carefully noted to designate the form and render the surface.

To order a print

click here to go to the PRINTS page.