Buy a print

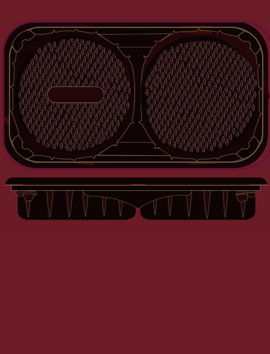

BURGER TRAY

The pack provides walls and separators to support the product on its journey from the food factory to the supermarket. These forms appear with indents and ribs which reinforce the shape and give it rigidity. The tiny ovals are used to stiffen the base of the moulding.

MAKING

The tray is vacuum formed where a heated sheet of flat plastic is clamped above a mould in a sealed chamber. The air is sucked out of the space and the sheet is pulled down to adopt the form of the mould. If you hold the moulding up to the light you may notice that the lower edges are thinner than the rest of the moulding. This is because the sheet has been stretched into the mould and the material at the corners has expanded more than the rest.

DRAWING

The fine details of the burger tray display some interesting features.The base is made from a pattern of tiny repeating ovals which reflect the light in a variety of ways, appearing to alternate from dimples to crescents.

To order a print

click here to go to the PRINTS page.