Buy a print

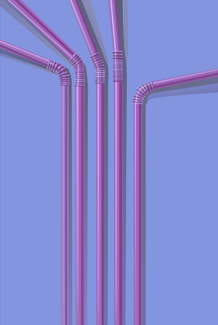

BENDY STRAWS

Until recently the plastic bendy straw was an essential ingredient of any children’s party. However, because they contribute to plastic pollution they have now been banned from restaurants and bars in many countries including the UK. Because they are so small they cannot be handled by the local authority recycling machines. If, however, they could be separated from other waste at the point of use this would not be the case. They are made from polypropylene or polystyrene which could be recycled more easily than paper which absorbs drinks and can only be thrown away. Because of their low cost this is not seen to be profitable. So, at your next children’s party your greenest option is to use reusable straws made of bamboo, metal or glass, unfortunately none of these are bendy.

HISTORY

The first known straw comes from 3000 BC Samaria where it was a status object made from a golden tube and inlaid with precious stones. By the 1800’s rye grass was a cheap and popular drinking straw but it tainted the drink with a grassy flavour. So in 1888, Marvin Chester Stone from Ohio patented the modern waxed paper drinking straw after wrapping paper around a

In the 1930‘s Joseph Friedman watched his daughter struggling to drink from a straight straw and came up with the idea of a bendy version. He patented his ‘Drinking Tube’ in 1937 but was unable to interest a number of drinking straw companies. Eventually, with family finance, he developed his own manufacturing machine and started production in1939 producing flexible straws for use in hospitals.

MANUFACTURE

The plastic straw is made by a process called extrusion in which softened plastic is pushed through a die to create a small tube. This is pulled through a long bath of cool water where it hardens to form a rigid tube. The tube is cut into short lengths before being fed into a machine which rolls the straws between heated formers to create the bendy section.

DRAWING

Each translucent straw gives a glimpse of the background and catches the light in particular ways.The shadows blur at the ends as they spread across the surface. The secondary, lighter shadows, often have brighter sections where they join the main area.Their colour and translucency has to be carefully observed to give the desired effect.